Antimicrobial surfaces?

Possible, with the right coating

The antimicrobial protection starts with the coating. We at IBIX are well aware of this and for over 20 years we have been offering solutions for total protection of metal and concrete surfaces against degradation caused by various factors: weather, pollution, general corrosion, frequent use, particularly corrosive atmospheres, etc.

Now, an additional factor available in surface protection is also proving to be fundamental in protecting people: POLYFUSION AM is the only solution that combines the efficiency, resistance, and durability of IBIX anti-corrosive thermoplastic coatings, which have always been known for their advanced performance in the most diverse industrial and civil sectors, with the effectiveness of silver ions in the fight against microbes and bacteria.

Effective against a wide range of microbes

Bacteria, mould, fungus, and even viruses.

Antimicrobial

It reduces the presence of widespread bacteria and micro-organisms, such as MRSA - Methicillin-resistant Staphylococcus aureus -, E-coli, Salmonella, Bacillus Suptilis, etc.

Does not contain Biocides

Protection is guaranteed by the nanotechnology of the silver ions.

Long-lasting

Provides a long-lasting barrier effect against microbe strains.

Easy to clean, requires low maintenance costs

IBIX thermoplastic coatings have always been resistant to the most aggressive acidic and alkaline agents, ensuring advanced and long-lasting chemical resistance. Thanks to its intrinsic characteristics, POLYFUSION AM is not affected by the substances contained in cleaning agents and the most common sanitizing products such as:

- Sodium hypochlorite (bleach);

- Acetic acid;

- Ethyl acid with quaternary salts.

POLYFUSION AM also perfectly resists frequent and intense cleaning cycles, even at high pressure.

Antimicrobial performance against E.Coli bacteria

Sample CFU at 0 hours CFU at 14 hours Comparison between Polyfusion and Polyfusion AM Propylene film 1.6x105 1.2x105 20% reduction Standard Polyfusion 1.6x105 1.5x105 n/a Polyfusion AM 1.6x105 <10 Reduction of 99.9999%

| Sample | CFU at 0 hours | CFU at 14 hours | Comparison between Polyfusion and Polyfusion AM |

| Propylene film | 1.6x105 | 1.2x105 | 20% reduction |

| Standard Polyfusion | 1.6x105 | 1.5x105 | n/a |

| Polyfusion AM | 1.6x105 | <10 | Reduction of 99.9999% |

High Performance

POLYFUSION AM reduces the presence of bacteria by 99.9999%, compared to the 20-38% with polyethylene film.

Polyfusion, the right choice!

POLYFUSION AM is the ideal choice for coating all walkable and wheel accessible, and touchable surfaces.

Metal, mild steel, galvanized steel, aluminum, concrete, and fibreglass, etc. with POLYFUSION AM, practically any surface can become antimicrobial.

POLYFUSION AM is primarily used in industries such as:

- Health industry; from the walls to the floor, and much more: even handrails, handles, furnishings, any surface subject to direct contact with the hands.

- Industrial sectors: pharmaceutical, food, agricultural, breeding.

- Surfaces for civil use: construction, public environments, changing rooms, public and private baths, gyms, supermarkets, household surfaces, playgrounds, and products for children.

Certified for contact with food products

- 100% non-toxic and eco-friendly coatings;

- Certification with foods in many countries throughout the world.

- Approved for permanent contact with wine/alcohol (wine cellars) and acetic acid.

IMMEDIATE COMMISSIONING.

IBIX thermoplastic coatings are easy to install and ready-to-use immediately

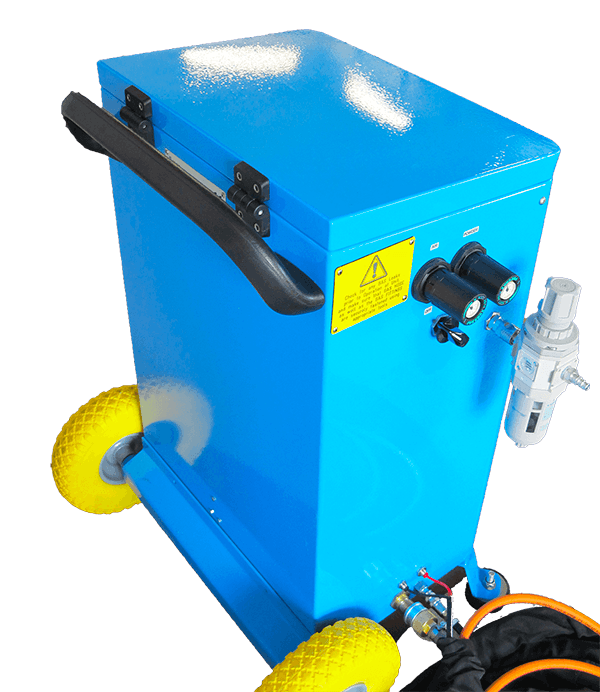

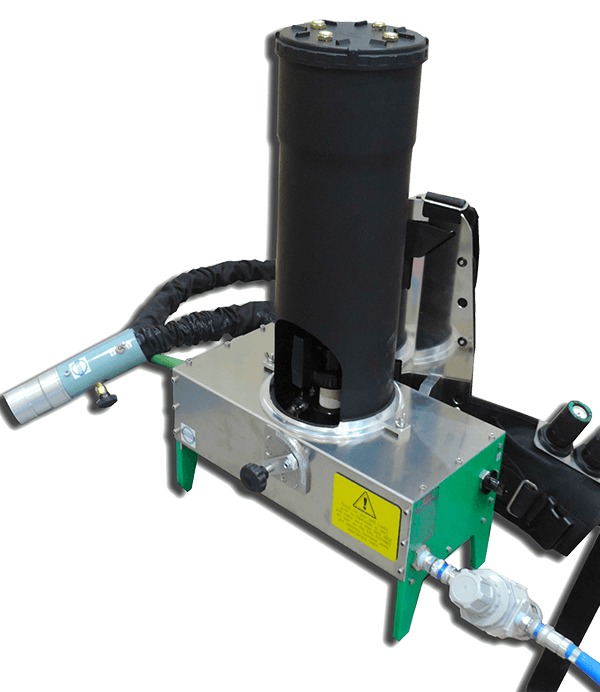

Gladiator Pro

Herlcules

SPARTACUS

Semi-Automatic

Atlantis Flame

Spray – Flock Spray

Flame Spray Pocket

Unlike thermosetting coatings such as polyurea or epoxy resins, thermoplastic polymers applied using Flame Spray technology by IBIX can be used immediately after application, support light traffic after only a few seconds, and heavy traffic after only 24 hours.

GREATER DEFENCE, FOR LONGER!

Compared to other painting and coating systems, IBIX thermoplastic powders guarantee:

- Impermeabilization: greater resistance to the penetration of liquids and vapours

- Excellent resistance to chemical agents (acids, alkali, solvents)

- Electric insulation

- Excellent resistance to adverse weather conditions, UV rays, and salt mist

- Do not fade over time, even in extreme outdoor applications

- Excellent stain resistance

- Excellent conduct in the event of fire (class 0)

- Excellent adhesion

- Excellent resistance to abrasion (Taber ASTM 60mg/500g)

- Exceptional flexibility, even at rigid temperatures

- Resistance to flaking, cracking, and other signs of deterioration under normal use

- Temperatures from -50°C to 70°C, without thermal shocks

- Smooth and durable finish Anti-slip texture available

- Repairs and retouches always possible and quick to perform

- 100% eco-friendly

Don’t wait, Contact us!

You can subscribe to our promotions, request information on products, or assistance to startup your projects.