ATLANTIS SEMI-AUTO 4.0

ATLANTIS SEMI-AUTO 4.0 is the portable system for spraying thermoplastic powders with dual mode of use flame spray and flock spray, in the semi-automatic version, which includes:

- FLOCK-SPRAY EQUIPMENT: for electrostatic spraying in the manual mode, fitted with fluidized bed tank and electrostatic gun. Power supply 220 V Frequency: 50 Hz

- FLAME SPRAY SYSTEM, SEMI-AUTOMATIC, equipped with:

- Mobile trolley with large pneumatic wheels.

- Quick connection.

- 9 m hoses + 6 m extension hoses.

- Fixed controls on the machine frame and electrical cabinet.

- Stainless steel tank.

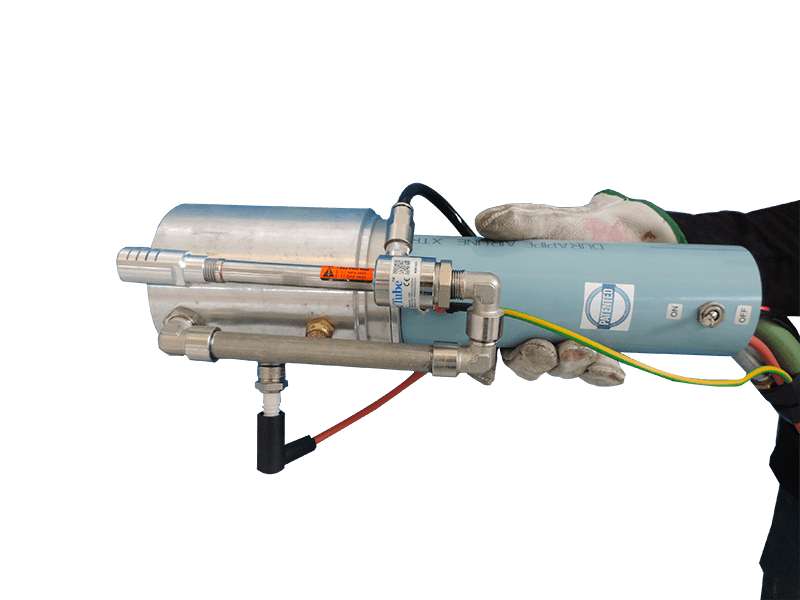

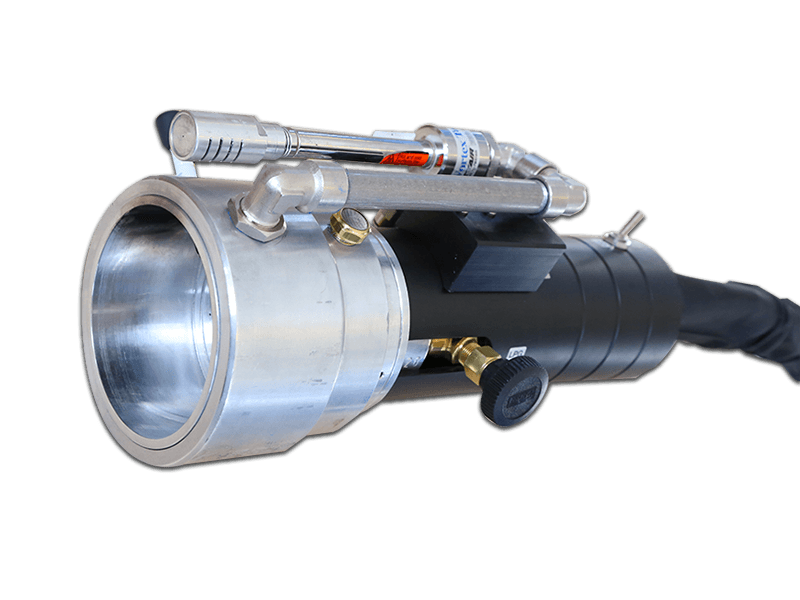

- Flame Spray Application Gun with automatic flame ignition device, available in several versions according to the coating purpose (metal, concrete and other porous substrates) and in various sizes/types.

- 4.0 EQUIPMENT: electrical panel with interconnection electronic card and modem, temperature-measuring pyrometer with 9 m connection cable.

The IBIX FLAME SPRAY 4.0 equipment is also available for the SPARTACUS and HERCULES SEMI-AUTOMATIC models

Models available

- With handle and trigger for coating of metals

- Straight handle and heat exchanger for concrete

Size options

Medium or Large

Spray pattern

14 cm (with LARGE guns)

Flame ignition system

AUTOMATIC

Models available

- With handle and trigger for coating of metals

- Straight handle and heat exchanger for concrete

Size options

Large

Spray pattern

30 cm

Flame ignition system

AUTOMATIC

Specific features of the several units

IBIX FLAME SPRAY INDUSTRY VERSION 4.0

Requirements

Pneumatic supply + single phase power supply.

Connectivity

Modem + SIM Data for working on-site (no LAN line).

IBIX Flame Spray

IBIX FLAME SPRAY system fitted with electrical panel with electronic card and modem for interconnection.

Control Device

The IBIX FS 4.0 equipment will receive the recipe / order data from the company computer or tablet *.

* Note: if a data is not entered, the system will NOT get stuck

All IBIX FS 4.0 models come supplied with the following

REMOTE CONTROL

Controls and transmissible Data

- Remote controlled on / off

- Sending of "recipe - work order" with some project data:

- Date Name / definition of the project

- Name of the client

- Surface type: metal or non-metal (concrete, ceramic, fiberglass, other)

- Type of powder to use

- Use of primer? YES - NO

- Thickness of the coating according to specifications

- Sq meters to be covered

Data forwarded from the machine to the CLOUD

- Work start time

- Work end time

- Processing time

- Number of stops

- Substrate temperature prior to the coating cycle

- Pre-heating temperature / s detected

- Last pre-heating temperature detected

Data previously entered manually by the operator:

- Thickness of the coating performed

- Kg of primer used

- Kg of powder used

- Kg of gas used

Further data transmitted from the device to the Cloud and downloadable from the company computer

- Gas flow adjustment / setting from smartphone

- Adjustment / setting of operating air pressure

- Gas flow value during processing

- Air pressure value during processing

- Geo-location of the machine

- Notes (short text of 120 characters)

By consulting the database, you will also see the following values:

- Total number of starts / stops

- Total working time of the machine